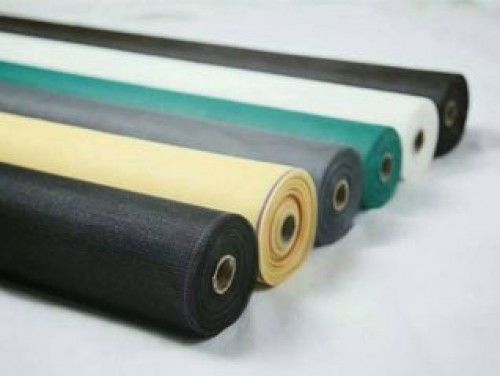

Fiberglass Mesh Screen for Cement Reinforcing: Enhancing Durability and Strength

In the dynamic construction world, introducing fiberglass mesh screens in cement reinforcing has marked a significant advancement, revolutionizing traditional building practices. This innovative material, known for its exceptional strength and durability, has become a cornerstone of modern construction methodologies. Fiberglass mesh is redefining the standards of structural integrity and efficiency, offering a compelling blend of corrosion resistance, lightweight properties, and environmental sustainability. This blog delves into the transformative impact of fiberglass mesh in cement reinforcement, exploring its advantages, applications, and pivotal role in shaping the future of construction. Join us in uncovering how fiberglass mesh sets new benchmarks in building robust, durable, and sustainable structures. Understanding Fiberglass Mesh Fiberglass mesh, a product woven from fiberglass threads, is known for its exceptional strength and durability. This mesh is used extensively in construction, particularly for reinforcing cement and other composite materials. Unlike traditional metal reinforcing materials, fiberglass mesh is resistant to rust and corrosion, making it a superior choice for longevity. The Role in Cement Reinforcement Cement structures, while robust, can be prone to cracking and weathering over time. Fiberglass mesh screens are integrated into cement to prevent cracks from spreading and enhance structural integrity. The mesh acts as a supportive skeleton within the cement, distributing stress and strain evenly and reducing the risk of structural failures. Advantages of Fiberglass Mesh in Cement Reinforcement 1. Corrosion Resistance: Unlike metal reinforcements, fiberglass mesh does not rust. This resistance to rust makes it ideal for use in harsh environments, including coastal areas or structures exposed to chemicals. 2. Strength and Durability: Fiberglass mesh significantly increases the tensile strength of cement structures. This added strength is crucial in high-stress applications such as flooring, foundations, and walls. 3. Lightweight: Being remarkably lighter than traditional metal reinforcements, fiberglass mesh reduces the structure's overall weight. This reduction is advantageous in large-scale constructions where weight management is crucial. 4. Flexibility and Versatility: The flexibility of fiberglass mesh makes it easy to apply in various shapes and sizes. This versatility is particularly beneficial in complex architectural designs. 5. Cost-Effectiveness: Fiberglass mesh can be more cost-effective compared to traditional metal reinforcements. Its durability and low maintenance requirements contribute to long-term savings. 6. Thermal Insulation: Besides reinforcement, fiberglass mesh offers thermal insulation properties, contributing to building energy efficiency. 7. Environmental Impact: Fiberglass mesh is an environmentally friendly alternative to metal reinforcements. Its production process is less energy-intensive, and the material is recyclable. Applications in Modern Construction Fiberglass mesh screens have found their place in numerous construction applications, including: •Reinforcing concrete in building foundations and walls. •Strengthening floorings, especially in industrial and commercial buildings. •Use in roads and bridges where durability under heavy traffic is critical. •In precast concrete elements, offering flexibility and strength. Installation and Best Practices Installing fiberglass mesh in cement is straightforward but requires precision to ensure optimal reinforcement. The mesh should be placed at the correct depth within the concrete to avoid exposure to the surface. Overlapping the mesh sheets correctly is crucial to maintain the integrity of the reinforcement. Future of Fiberglass Mesh in Construction The future of construction sees an increasing shift towards materials that offer sustainability, strength, and cost-effectiveness. Fiberglass mesh, with its remarkable properties, is at the forefront of this shift. Continuous innovations in the composition and application of fiberglass mesh are anticipated, making it an even more integral part of modern construction techniques. Challenges and Considerations While fiberglass mesh offers numerous advantages, it’s essential to consider its limitations. For instance, it has lower heat resistance compared to metal reinforcements. Therefore, its application in high-temperature environments should be carefully assessed. Conclusion: Fiberglass mesh screen for cement reinforcing represents a significant advancement in construction materials. Offering an unparalleled combination of strength, durability, and versatility; it addresses many of the limitations of traditional reinforcement materials. As the construction industry continues to evolve, the role of fiberglass mesh in creating resilient, efficient, and sustainable structures becomes increasingly vital. Its continued adoption and integration into various construction projects underscore its importance in the ever-evolving world of construction and architecture.

View DetailsIs fiberglass better than polyester for mosquito nets?

When selecting the suitable material for mosquito nets, weighing the pros and cons of different fabrics is crucial. Two popular choices are fiberglass and polyester, each offering unique benefits and challenges. Mosquito nets are vital in protecting individuals from insect-borne diseases, making their effectiveness, durability, and safety paramount. In this comprehensive analysis, we'll delve into the specifics of fiberglass and polyester mosquito nets, comparing their strength, cost, environmental impact, and overall suitability for various settings. Understanding these factors is essential for making an informed decision that ensures comfort, protection, and long-term usability. Durability and Strength Fiberglass: •Fiberglass nets are known for their durability. They are less prone to tearing and can withstand harsh conditions. •They are also resistant to rust and corrosion, making them ideal for humid or coastal environments. •Fiberglass nets maintain shape over time and are less likely to sag. Polyester: •Polyester nets are also durable but may be more prone to wear and tear than fiberglass. •They are less resistant to high temperatures and might degrade faster in harsh weather conditions. •Polyester nets can lose shape over time, especially if frequently moved or adjusted. Effectiveness in Mosquito Prevention Fiberglass: •Fiberglass nets have a rigid structure, which can effectively prevent mosquitoes from entering. •The mesh size can be fine-tuned to balance mosquito prevention and airflow. •They are often coated with PVC or other materials, enhancing their mosquito-repellent properties. Polyester: •Polyester nets are highly effective at preventing mosquitoes due to their fine mesh. •They are more flexible, allowing for a tight fit in various spaces and leaving fewer gaps for mosquitoes to enter. •However, they might require more frequent inspections for tears or holes where mosquitoes could penetrate. Cost and Availability Fiberglass: •Fiberglass nets are generally more expensive due to their material and manufacturing process. •They are widely available but might offer fewer options in terms of size and shape. Polyester: •Polyester nets are more affordable, making them a cost-effective option for large-scale or budget-conscious projects. •They are readily available in various sizes and shapes, providing flexibility for different applications. Environmental Impact and Safety Fiberglass: •Fiberglass production has a higher environmental impact, and disposal can be challenging. •They are non-biodegradable, which can contribute to long-term ecological concerns. •Fiberglass strands can be harmful if inhaled or come into contact with the skin. Polyester: •Polyester is a synthetic material, and its production has an environmental impact. •However, polyester nets are often lighter and require less material, which can reduce their overall carbon footprint. •They are safer for direct human contact and do not pose the same health risks as fiberglass. Maintenance and Cleaning Fiberglass: •Fiberglass nets are easier to clean due to their rigid structure and can be wiped down. •They are less likely to absorb odors or become stained. Polyester: •Polyester nets require more careful cleaning to avoid damage. •They can absorb moisture and odors, necessitating more frequent cleaning. Aesthetic and Flexibility Fiberglass: •Fiberglass nets typically have a more industrial look, which might only be ideal for some settings. •They offer less flexibility in terms of design and aesthetics. Polyester: •Polyester nets are available in various colors and can be more aesthetically pleasing. •They offer more design flexibility and are suitable for different architectural styles. Conclusion: Both fiberglass and polyester mosquito nets have their advantages and disadvantages. Their choice depends on specific needs such as budget, environment, safety concerns, and aesthetic preferences. For long-lasting, low-maintenance applications, fiberglass might be the better choice. However, polyester nets could be more suitable for cost-effectiveness, flexibility, and ease of use. Ultimately, the decision should be based on the specific requirements of the intended use and the environment in which the nets will be used.

View DetailsTips To Attach Mesh To A Fence DIY

Attaching mesh to a fence is a practical way to enhance security and privacy or to create a barrier for animals and pests. Whether you're dealing with a chain link fence, wooden fence, or any other type, there are several effective methods and tips to consider for a successful mesh attachment. This comprehensive guide will explore the best ways to attach mesh to a fence, offering suggestions to ensure durability, effectiveness, and aesthetic appeal. 1. Understanding the Type of Mesh and Fence Mesh Type: Different types of mesh, such as wire, plastic, or fabric, require specific attachment methods. Wire mesh is durable and suitable for security purposes, while plastic mesh is lightweight and often used for garden fencing. Fabric mesh is often used for privacy screens. Fence Material: The material of your fence (metal, wood, vinyl, etc.) dictates the tools and techniques you'll need. Metal fences may require wire ties or clips, while wood fences are more suited for staples or nails. 2. Preparing for Installation Measure and Plan: Measure your fence's length and height accurately. Plan how you'll roll out the mesh and the spacing of your attachment points to ensure even tension and a neat appearance. Gather Tools and Materials: Gather necessary tools such as wire cutters, staple guns, pliers, or drills, depending on your mesh and fence type. Also, have enough fasteners, like staples, ties, or screws. 3. Attachment Methods Using Staples for Wooden Fences: For wooden fences, a heavy-duty staple gun is effective. Ensure the staples are galvanized to prevent rusting. Staple along the mesh's top, middle, and bottom, spacing them every 6-12 inches. Wire Ties for Chain Link Fences: For chain-link fences, wire ties are ideal. Bend the relationship around the mesh and the wall regularly, twisting the ends with pliers to secure. Screws and Washers for Durability: In some cases, especially with heavier mesh types, using screws with washers can provide extra durability. This method works well on both wood and metal fences. U-Nails for a Strong Hold: U-nails, or fence staples, are great for attaching wire mesh to wooden fences. They offer a stronger hold than regular staples, especially in windy areas. 4. Ensuring Tension and Alignment Keep It Taut: While attaching the mesh, it's essential to keep it taut to prevent sagging. This may require two people: one to hold the mesh tight and the other to attach it. Check Alignment: Regularly step back and check the alignment of the mesh. An unevenly attached mesh can be unsightly and less effective. 5. Finishing Touches Trimming Excess Mesh: Once attached, trim any excess mesh for a clean look. Be careful to avoid leaving sharp edges. Painting or Treating: Consider painting metal mesh or treating wooden fences with a protective coat to improve aesthetics or increase durability. 6. Maintenance Regular Inspections: Periodically inspect the mesh for any damage or loosening, especially after severe weather. Rust Prevention: If you're using metal mesh or fasteners, check for rust. Apply rust-inhibiting paint or replace rusted parts as necessary. 7. Safety Considerations Wear Protective Gear: Always wear gloves and safety glasses to protect against sharp edges and flying debris. Be Mindful of Surroundings: Ensure your work does not damage underground utilities or infringe on neighboring properties. Tips for fiberglass mesh fencing: Fiberglass mesh fencing is a popular choice due to its durability, flexibility, and resistance to rust and corrosion. Here are some of the best tips for installing and maintaining fiberglass mesh fencing: Choose the Right Grade: Select the appropriate grade of fiberglass mesh based on your needs. Heavy-duty mesh is ideal for high-security areas, while lighter grades are suitable for residential properties. Use Suitable Posts: Choose solid and durable posts that can support the weight of the fiberglass mesh. Materials like steel, aluminum, or treated wood are recommended. Proper Spacing of Posts: Ensure posts are evenly spaced to provide adequate support and maintain the tension of the mesh. Install Bottom Rails: For added stability, install bottom rails to prevent sagging and keep the bottom edge of the mesh off the ground. Attach Mesh Securely: Use appropriate fasteners such as stainless steel staples, screws, or ties. Ensure the mesh is pulled taut during installation to avoid sagging. Overlap Panels Correctly: If your fence requires multiple mesh panels, overlap them by at least one inch to ensure no gaps and maintain strength. Weatherproofing: Although fiberglass is weather-resistant, applying a UV-resistant coating can protect the mesh from sun damage and fading. Install Gates Carefully: If your fence includes gates, ensure they are well-aligned, and the mesh is attached correctly to avoid gaps or sagging. Consider Visibility: Fiberglass mesh can be semi-transparent. If privacy is a concern, consider layering or using a type with tighter weaves. Wrap up Attaching mesh to a fence can significantly improve its functionality and appearance. You can ensure a successful and durable installation by choosing the suitable materials, tools, and methods for your specific situation and following these tips. Remember, doing it right will save you time and resources in the long run, providing a secure and attractive boundary for your property.

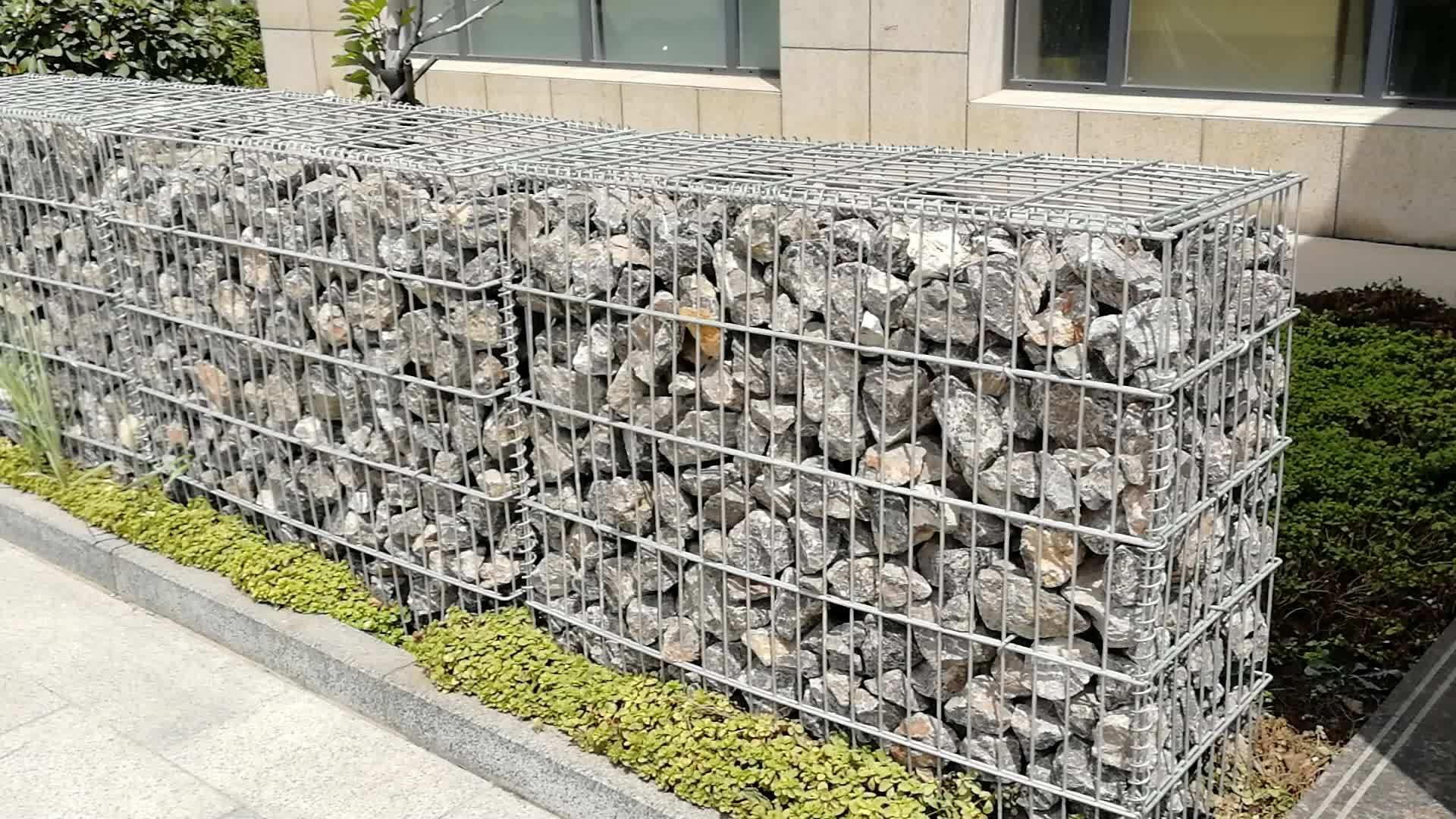

View DetailsHow to build a Gabion Wall?

Building a gabion wall is an innovative and stylish way to create structures for landscaping or home projects. Here's a detailed guide on how to make one, complete with ideas and critical considerations: 1. Planning and Design of Gabion Walls The planning and design of a gabion wall require a thoughtful approach. Balancing functionality with aesthetics while considering site-specific conditions and landscape integration is critical. A well-planned gabion wall serves its intended purpose and enhances the property's beauty and value. Understanding the Purpose Firstly, determine the primary purpose of the wall. Is it for aesthetic enhancement, creating a boundary, or serving as a retaining structure? The function dictates the design specifics, such as height, thickness, and location. For instance, retaining walls require more structural integrity compared to decorative walls. Site Analysis Choose a stable, level site for your gabion wall. Consider factors like soil type, drainage patterns, and proximity to existing structures. Assess the potential impact on the surrounding area, including how the wall might alter natural water flow or affect neighboring properties. For retaining walls, understanding soil pressure and slope stability is essential. Design Considerations Once the purpose and site are clear, focus on the wall's design. Gabion walls offer flexibility in shape and size. Depending on your landscape and aesthetic preferences, they can be straight, curved, tiered, or sculptural. Size and Scale The wall's dimensions should be proportional to the space. A large garden can accommodate a taller or longer wall, while a smaller space might benefit from a shorter, decorative feature. Choice of Materials The type and size of stones or other fill materials affect the wall's appearance and stability. Larger stones are typically used to retain walls for added strength, while more minor, colorful stones might be chosen for decorative walls. Integration with Landscape Consider how the wall will interact with existing landscape elements. Will it be a standalone feature or integrated with other structures like patios or garden beds? The design should complement and enhance the overall landscape theme. Aesthetic Appeal Gabion walls are as much about aesthetics as they are about function. The visible stone fill offers an opportunity to add a decorative element. Choosing different colors, textures, or types of stones can create a unique look. Incorporating patterns or alternating other fill materials can turn a simple gabion wall into a work of art. Technical Aspects Pay attention to technical details like the type and strength of the wire mesh. The mesh size should be appropriate for the fill material to prevent stone loss. Also, consider additional support structures, especially for taller walls. 2. Materials Needed It would help to have durable gabion baskets made of galvanized steel with an appropriate mesh size for a gabion wall. The fill material, usually stones or rocks, should be weather-resistant and aesthetically pleasing. Choose stones that complement your landscape, considering color and texture variation. Other materials include sturdy gloves, wire cutters for assembling the baskets, levels to ensure eveness and landscapping fabric.Selecting high-quality materials ensures longevity and reduces maintenance needs, making your gabion wall a functional and attractive feature in your landscape. 3. Foundation Preparation Foundation preparation is critical for a stable gabion wall. Start by excavating a trench, the depth of which depends on the wall's height—generally, a quarter of the wall's height. Fill the trench with a compacted base of gravel or hardcore to provide a solid and level foundation. This step is crucial for preventing the settling or tilting of the wall. Ensure that the foundation extends beyond the wall's width for additional support. Proper foundation preparation is critical to the wall's longevity, preventing future issues like misalignment or collapse, especially in load-bearing or retaining wall applications. 4. Assembling the Gabions Assembling gabions involves positioning the wire baskets at the designated location and securely interlocking them using galvanized wire. It's a crucial step, and that's why it is essential to do it with great care by following the instructions properly: Unpacking and Layout Unpacking: Carefully unpack the gabion baskets. They usually come flat-packed. Layout: Lay out the sections on a flat surface. This includes the base, sides, ends, and lids. Assembling the Baskets Shaping the Basket: Stand up the sides, ends, and base to form the box shape. Most gabion baskets are designed to be easily bent into shape by hand. Securing Corners and Edges: Use the provided ties or spirals to secure all corners and edges. This is crucial for the structural integrity of the basket. Special Tools: For larger projects, a gabion assembly tool or hog ring plier can speed up the process and ensure a more secure assembly. Joining multiple baskets: If your project requires multiple baskets, place them adjacent to each other. Securely tie the adjoining edges together. This ensures they act as one continuous structure, which is significant for retaining walls. 4. Filling the baskets Type of Fill Material: Choose appropriate stones or other materials for filling. Ensure they are larger than the mesh size to prevent them from falling out. Filling Method: Begin filling the baskets with the chosen material. Hand-placing the stones at the faces is often recommended for a neater appearance. Layering: Fill the baskets in layers, compacting each layer before adding the next. This prevents voids and ensures stability. Closing the Baskets Once filled, close the lid of the basket. Secure the lid with ties or spirals, ensuring it's tightly closed to prevent the fill material from escaping. Tips for Stability Internal Bracing: To prevent bulging, internal bracing with wires or rods might be necessary for taller baskets. Checking for Gaps: Regularly check for gaps in the fill material and fill them to maintain the shape and strength of the wall. Uniform Distribution: Ensure the weight is uniformly distributed to avoid tilting or misalignment. Safety Considerations Wear gloves and safety glasses during assembly to protect against sharp wires. Ensure the area around the assembly is clear and safe for working. Final Inspection Once assembled and filled, inspect the gabion baskets for any loose ties or protruding wires. Make any necessary adjustments to ensure the structure is secure and stable. Following these detailed steps, you can assemble gabion baskets for your project, ensuring they are well-constructed, stable, and aesthetically pleasing. 6. Creative Ideas and Tips 1. Plant Integration ideas Integrating plants into and around gabion structures can enhance their aesthetic appeal, creating a harmonious blend of natural and man-made elements. When selecting plants for integration, choosing species that complement the gabion environment is essential. This includes considering the local climate, soil conditions, and the amount of sunlight the area receives. Resilient shrubs and flowers that require minimal maintenance, like native species or drought-tolerant plants, are ideal choices. Planting in the gabions themselves involves creating small soil pockets within the structure, where smaller, robust plants can thrive. Around the gabions, larger shrubs and flowering plants can be planted to soften the hard edges of the stone and add color and texture. This approach not only enhances the visual appeal of the gabion walls but also encourages biodiversity and can provide habitats for local wildlife. The end result is a beautiful, living structure that changes and grows over time, fully integrating the gabion into the natural landscape. 2. Lighting: Enhancing Gabion Walls at Night Adding lighting to gabion walls transforms them into striking landscape features at night. The strategic placement of lights can accentuate the texture and color of the stones, creating a dramatic visual effect. Consider using LED spotlights at the base to cast an upward glow, highlighting the wall's structure. Solar-powered lights are an eco-friendly option, offering ease of installation without electrical wiring. For a more subtle ambiance, embed small LED lights within the gabion, allowing the light to seep through the stones. This not only enhances the beauty of the wall but also adds safety and visibility to outdoor areas after dark. 3. Mixed Materials: Creating a Unique Look Using a mix of different stones or materials in gabion walls can create a distinctly unique and artistic look. Experiment with various sizes, colors, and textures of stones to achieve a visually appealing mosaic effect. For a more avant-garde design, intersperse unconventional materials like colored glass, ceramic pieces, or recycled materials like metal objects or bricks. The key is to ensure that all materials are durable and weather-resistant. This approach allows for a high degree of customization, enabling the gabion wall to reflect personal style and complement the surrounding landscape. 4. Seating: Functional and Aesthetic Integration Incorporating seating into gabion walls is a practical way to add functionality while enhancing the landscape's aesthetic. The top portions of gabion walls can be fitted with wooden or stone slabs to create benches. This integration serves as both a resting spot and an intriguing design element. When using wood, choose weather-resistant types like teak or cedar; flat, smooth slabs ensure comfort for stone. These seating areas can become social spots in gardens or peaceful retreats in private landscapes. The natural look of gabion materials combined with wood or stone creates an inviting and harmonious blend. 5. Water Features: Harmonious Combinations Designing gabion walls around ponds, fountains, or waterfalls adds a dynamic element to the landscape. The gabions' rugged texture contrasts beautifully with the water's fluidity, creating a sense of balance and tranquility. For ponds, gabion walls can serve as retaining structures or decorative borders. Incorporating a fountain or waterfall with a gabion backdrop can produce a stunning visual and auditory experience as water cascades over the stones. This combination enhances the aesthetic value of the space and contributes to a calming atmosphere, making it a perfect addition to gardens, courtyards, or communal outdoor areas. 7. Maintenance Maintaining a gabion wall involves periodic inspections to ensure the wire cages' integrity and the fill material's condition. Check for any signs of corrosion or damage to the wire mesh, especially in harsh weather conditions. If any settling of stones occurs, additional filling might be required to maintain the wall's shape and stability. Vegetation growing into the structure should be managed to prevent damage. Regular maintenance ensures the longevity of the wall and preserves its aesthetic appeal. Although gabion walls are known for their durability, proactive care can prevent minor issues from escalating into major repairs.

View DetailsAffordable Gabion Filling Strategies for Lasting Structures

Explore cost-effective gabion filling methods that won't break the bank. Discover how to use local materials and innovative solutions for your gabion projects. The cheapest way to fill a gabion will often depend on the readily available materials in your local area. Here are some commonly used, cost-effective options: Local Stone: Local stones are a cost-effective option for filling gabions because they typically require less transportation, significantly reducing costs associated with fuel and logistics. Sourcing stone from nearby quarries or natural deposits eliminates the need for long-haul shipping, lowering expenses and reducing the carbon footprint, making it an environmentally sustainable choice. Additionally, using local stones ensures that the materials are readily available and can be easily replaced or supplemented if needed, further enhancing cost-efficiency and convenience for construction and landscaping projects. Recycled Materials: Recycled materials are an excellent alternative as fill material for gabions for several reasons. They are often less expensive than new materials because they are repurposed from waste products, such as construction debris, which would otherwise require disposal. This repurposing also supports sustainability by reducing landfill waste and the energy consumption associated with manufacturing new materials. Moreover, recycled materials like crushed concrete or broken bricks can provide the same structural support as new materials. One can contribute to a circular economy by choosing recycled fillers, reinforcing environmental responsibility while maintaining the integrity of the gabion structures. Quarry by-products: Quarry by-products are an excellent alternative to gabion fillers due to their cost-effectiveness and availability. These by-products, often regarded as waste, include quarry dust, chips, and overburden that are readily available at a fraction of the cost of prime quarry stone. Using these materials provides a use for what would otherwise be discarded, reduces quarry waste, and significantly reduces material costs. They can be particularly suitable for the internal layers of gabions, where aesthetics are less critical, utilizing robust, durable materials without incurring the higher expense of more refined stone products. Non-decorative fill materials: Non-decorative fill materials are an ideal alternative for gabion baskets because they are generally more affordable than decorative stones. Such materials, including quarry leftovers, recycled concrete, or rubble, can be effective for structural purposes but come at a lower cost. For gabions that serve a functional purpose rather than an aesthetic one, like erosion control or retaining walls, the appearance of the fill material is less important. This allows for using less expensive, non-decorative options without compromising the functionality of the gabion structures. Additionally, a layer of decorative stone can be placed on the exterior for partially visible gabions for visual appeal. At the same time, the bulk of the basket is filled with cheaper material, combining cost savings with an attractive finish. Rubble: Rubble is a cost-effective fill material for gabions, primarily due to its accessibility and reduced processing costs. It is often sourced from construction and demolition waste, which would otherwise require landfill disposal. By repurposing this rubble, disposal costs are avoided, and the material is obtained at a lower price, if not for free. Rubble processing into a usable form for gabions, such as breaking down larger pieces into smaller, manageable sizes, is minimal compared to the extraction and transportation costs of new materials. Therefore, using rubble as fill reduces overall construction expenses while promoting recycling and sustainable practices. Earth-filled material: Earth-filled gabions can be suitable for specific projects, offering a very economical alternative. Earth is often readily available on-site, eliminating the need for transportation and the associated costs. Additionally, using earth fill can integrate the gabion structure more naturally into the surrounding landscape, as the fill material is consistent with the local environment. However, it's important to note that earth-filled gabions are generally less durable or structurally sound than those filled with stone, particularly in wet conditions. They are best used in applications where water drainage is not a critical issue and the additional structural strength of the stone is optional. How many stones does it take to fill a gabion? The number of stones required to fill a gabion depends on several factors, including the size of the gabion basket and the size of the stones used. To calculate the number of stones needed, you would first determine the volume of the gabion basket (length x width x height). Once the volume is known, you can estimate the amount of stone needed to fill that volume. For example, if the stones are relatively uniform, they can pack them tightly, reducing the void space. However, natural stones often vary in size, which increases the null space and thus requires more stones to fill the same volume. The standard practice assumes that the void space will take up approximately 30–50% of the gabion volume, depending on the stone's size and shape. For an accurate estimate, it's best to consult with a supplier or use a gabion stone calculator, which considers the specific dimensions and recommended fill material for your project. What is the density of gabion fill? The density of gabion fill can vary widely depending on the type of material used. Typical stone or rock fill for gabions has a density ranging from 1.5 to 3 tons per cubic meter (93 to 187 pounds per cubic foot). The specific gravity of the stone and the amount of void space between the rocks will influence the overall density. For instance, lighter materials like volcanic rocks will have a lower density, while denser materials like granite or limestone will have a higher density. When planning a gabion project, it's essential to consult with material suppliers for precise density values based on the selected fill material. Conclusion: To minimize costs, you should also consider the transportation distance, the availability of materials, the labor required to fill the gabions, and any equipment needed for the job. It’s always a good idea to compare prices from different suppliers and consider the long-term durability of the fill material to ensure it’s cost-effective in the long run.

View DetailsUnderstanding The Size Of Gabion Boxes For Different Projects

Gabion boxes are a versatile and environmentally friendly solution in civil engineering, landscaping, and construction. They are composed of wire mesh containers filled with various materials, such as rocks or stones, and are used for applications like erosion control, retaining walls, and landscaping. The size of gabion boxes is a crucial factor in determining their effectiveness and suitability for different projects. In this blog post, we will delve into the various aspects of gabion wall baskets to help you make informed decisions while dealing with gabion suppliers for your projects. Why Understanding Gabion Box Size Matters? The size of gabion boxes plays a significant role in their performance and functionality. A gabion box's dimensions determine its capacity, stability, and the extent to which it can resist external forces, making it essential to choose the right size for each specific application. Let's explore the key factors to consider when determining the size of gabion boxes. Local Market Standard: In the United States, the gabion industry adheres to specific standards and guidelines to ensure product quality and reliability. The American Society for Testing and Materials (ASTM) provides standards for gabion box sizing and manufacturing processes. These standards help ensure that gabion boxes meet the necessary criteria for various applications. Here are some essential ASTM standards relevant to gabion boxes: a. ASTM A975: This standard specifies the requirements for double-twisted hexagonal wire mesh gabions and revet mattresses. It includes guidelines for mesh openings, wire diameter, and tolerances. b. ASTM A974: This standard focuses on the requirements for gabion wall baskets and gabion mattress material. It outlines the criteria for materials such as galvanized steel wire, zinc-coated steel wire, and PVC-coated steel wire used in gabion construction. c. ASTM A975M: Similar to ASTM A975, this standard provides metric dimensions for gabion boxes and mattresses. Gabion Box Sizes for Different Applications: Gabion Box Size for Erosion Control: 1. Erosion control is one of the primary applications of gabion boxes. Gabion structures can help stabilize shorelines, riverbanks, and slopes to prevent soil erosion. The size of gabion boxes is a critical factor when designing erosion control projects. According to data from the US Environmental Protection Agency (EPA), gabion boxes used for erosion control are typically more extensive, with dimensions ranging from 2 feet by 1 foot by 1 foot to 6 feet by 3 feet by 3 feet, depending on the project's scale. 2. Gibon Box Size for Retaining Walls: Gabion boxes often create retaining walls that offer functionality and aesthetics. The size of gabion boxes for retaining walls varies based on the desired height and load-bearing capacity. For instance, the Federal Highway Administration (FHA) recommends using gabion boxes with dimensions of 3 feet by 3 feet by 3 feet or 4 feet by 4 feet by 4 feet for small to medium-sized retaining walls. 3. Gabion Box Size for Landscaping: In landscaping, gabion boxes are decorative elements in gardens, parks, and outdoor spaces. The choice of gabion box size in these applications is more flexible, with smaller dimensions often preferred for decorative purposes. The data from landscaping projects across the US suggests that gabion boxes ranging from 1 foot by 1 foot by 1 foot to 2 feet by 2 feet by 2 feet are commonly used to create visually appealing features. The Impact of Wire Gauge on Gabion Box Size: The wire gauge used in gabion box construction has a direct influence on the box's overall size. Thicker wire gauges are more robust and can withstand greater forces, allowing for the construction of larger gabion boxes. In the US, gabion boxes are typically constructed using wire with gauges ranging from 10 to 12, with 10-gauge wire being more common for larger gabion boxes designed for heavy-duty applications. The Importance of Mesh Opening Size: The mesh opening size of gabion boxes is a critical factor that impacts their functionality. The opening size determines the size of the stones or rocks that can be used to fill the gabion boxes. According to ASTM A975 standards, the mesh openings can vary from 2 1/2 inches to 3 inches in size, depending on the intended use. Smaller openings are suitable for finer materials, while larger openings accommodate larger rocks. Factors Influencing Gabion Box Size Selection: Several factors should be considered when selecting the appropriate size of gabion boxes for your project. These factors include: 1.Project Scope: Consider the size and scale of the project, as more significant projects may require more giant gabion boxes. 2.Environmental Conditions: Assess the local environmental conditions, including weather, terrain, and soil composition, as these factors can affect the choice of gabion box size. 3.Load-Bearing Requirements: Determine the load-bearing capacity required for your project, which will influence the wire gauge and gabion box size. 4.Aesthetics: If the project has a visual component, such as landscaping or architectural design, choose the gabion box size that best suits the desired aesthetic. 6.Local Regulations: Ensure compliance with local regulations and building codes that may stipulate gabion box size requirements for specific applications. Size impacts the project's cost: The size of gabion boxes can have an impact on project costs. Larger gabion boxes typically require more materials for construction, including wire mesh and stone fill, which can increase the overall project budget. It is essential to balance the size of gabion boxes with project requirements and budget constraints. Sometimes, smaller gabion boxes may be a cost-effective solution, while larger boxes may be necessary for specific applications. Future Trends In Gabion Box Sizing: As the construction industry continues to evolve, there are several emerging trends related to gabion box sizing in the US. These trends are driven by sustainability, design innovation, and cost efficiency. 1. Sustainable Gabion Boxes: With a growing focus on sustainability, there is an increased interest in using gabion boxes made from recycled materials. The size of gabion boxes may be adapted to accommodate eco-friendly materials while maintaining strength and durability. 2. Modular Gabion Systems: Modular gabion systems are gaining popularity for their flexibility and ease of installation. These systems consist of smaller, interlocking gabion boxes that can be configured in various ways to create retaining walls, seating, and other structures. This trend will likely influence the size and design of gabion boxes. 3.3D Printing: Emerging technologies like 3D printing are being explored for creating customized gabion box sizes and designs. This could open up new possibilities for architects and builders to create unique and intricate structures. Conclusion: The size of gabion boxes is a crucial aspect of their effectiveness and suitability for different applications. Whether you're working on erosion control, retaining walls, or landscaping, understanding the right size of gabion boxes is essential for achieving your project's goals while ensuring safety and cost-efficiency. Remember that the choice of gabion box size should be based on project-specific requirements, environmental conditions, and local regulations to ensure successful outcomes. Gabion boxes, when sized correctly, can provide both functionality and aesthetic appeal while contributing to the long-term sustainability of your projects. Suppose you are ready with your requirements and considering where to buy gabion baskets. In that case, with just one click, you can be led to our exciting collection of gabion boxes, where you can easily find and select the best-suited gabion basket for your upcoming project. Be sure to check it because we are the best Gabion suppliers.

View Details